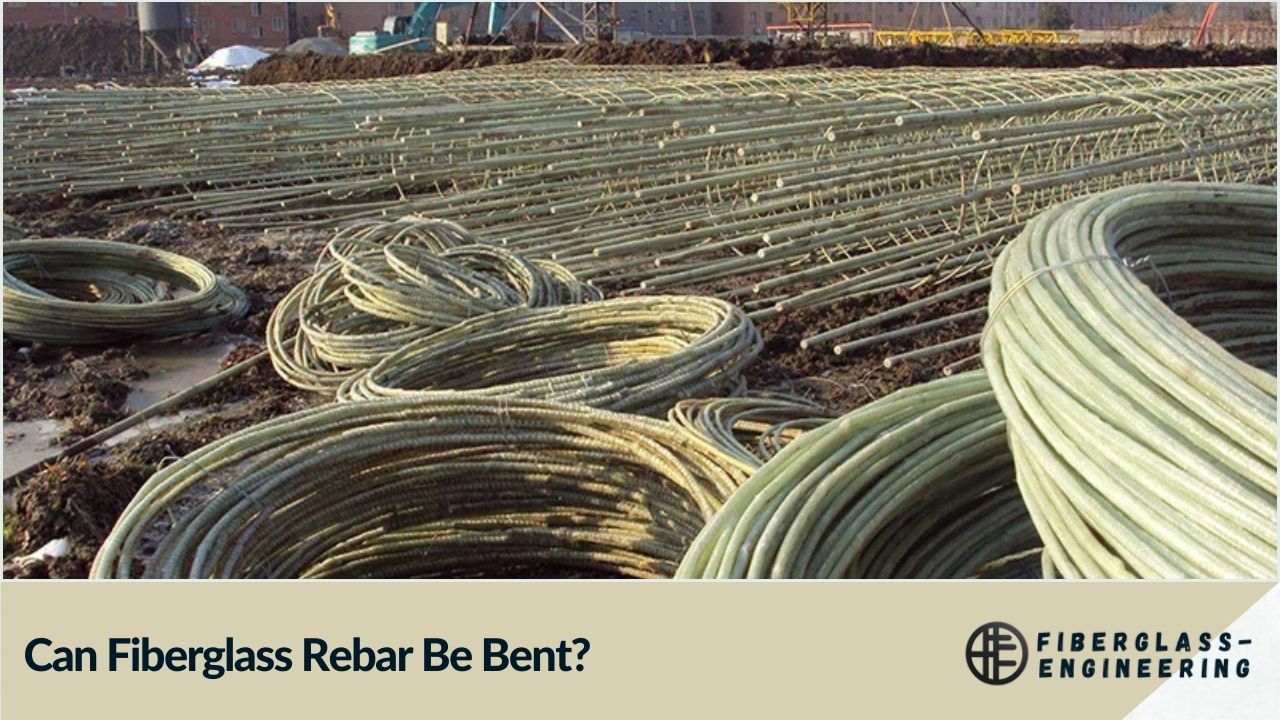

Fiberglass rebar, also known as Glass Fiber Reinforced Polymer (GFRP) rebar, has gained significant attention in the construction industry due to its unique properties and potential advantages over traditional steel rebar. One common question that arises when considering fiberglass rebar is whether it can be bent to accommodate various design requirements. In this comprehensive article, we will explore the bendability of fiberglass rebar, its advantages, limitations, and the precautions necessary to ensure optimal results.

Understanding Fiberglass Rebar

Fiberglass rebar is a composite material consisting of high-strength glass fibers embedded in a polymer matrix, typically epoxy resin. This combination results in a lightweight, corrosion-resistant, and durable material that offers several advantages over conventional steel rebar.

Key properties of fiberglass rebar include:

- High tensile strength

- Corrosion resistance

- Lightweight construction

- Electrical non-conductivity

- Thermal insulation

These properties make fiberglass rebar an attractive option for various construction applications, particularly in environments where corrosion is a significant concern.

Can Fiberglass Rebar Be Bent?

The short answer is yes, fiberglass rebar can be bent to a certain degree. However, it's crucial to understand that the bending process for fiberglass rebar differs significantly from that of steel rebar. The ability to bend fiberglass rebar depends on several factors, including:

- Flexural strength: Fiberglass rebar has a specific flexural strength that determines its ability to withstand bending without breaking.

- Diameter of the rebar: Smaller diameter fiberglass rebar is generally easier to bend than larger diameter options.

- Manufacturer specifications: Different manufacturers may have varying guidelines for bending their fiberglass rebar products.

- Bending technique: Proper techniques and tools are essential for successfully bending fiberglass rebar without causing damage.

Bending Techniques for Fiberglass Rebar

When bending fiberglass rebar, it's crucial to follow specific techniques to maintain the material's integrity and structural properties. Here are some key considerations:

- Gradual bending: Unlike steel rebar, which can be bent relatively quickly, fiberglass rebar requires a more gradual and controlled bending process.

- Use of appropriate tools: Specialized bending tools designed for fiberglass rebar should be used to ensure proper curvature and prevent damage.

- Temperature considerations: Some manufacturers recommend slightly heating the fiberglass rebar to increase its flexibility during the bending process. However, excessive heat can damage the material, so it's essential to follow manufacturer guidelines closely.

- Minimum bend radius: Each fiberglass rebar product has a specified minimum bend radius that should not be exceeded to prevent structural damage.

- Pre-bent options: For complex shapes or tight bends, it's often better to use pre-bent fiberglass rebar sections manufactured under controlled conditions.

Advantages of Bendable Fiberglass Rebar

The ability to bend fiberglass rebar, albeit with limitations, offers several advantages in construction applications:

- Design flexibility: Bendable fiberglass rebar allows for the creation of curved or non-linear reinforcement structures, expanding design possibilities.

- Customization: On-site bending capabilities enable customization to fit specific project requirements.

- Reduced waste: The ability to bend fiberglass rebar can lead to more efficient material use and less waste on construction sites.

- Simplified installation: In some cases, bendable fiberglass rebar can simplify the installation process, particularly in complex structural elements.

Limitations and Disadvantages of Fiberglass Rebar

While fiberglass rebar offers numerous benefits, it's essential to consider its limitations and potential disadvantages:

- Limited bendability: Compared to steel rebar, fiberglass rebar has more restricted bending capabilities, which can limit its use in certain applications.

- Potential for damage: Improper bending techniques or exceeding the minimum bend radius can lead to structural damage or weakening of the fiberglass rebar.

- Higher initial cost: Fiberglass rebar is generally more expensive than traditional steel rebar, which can impact project budgets.

- Lower modulus of elasticity: Fiberglass rebar has a lower modulus of elasticity compared to steel, which may require design adjustments in certain structural applications.

- Limited ductility: Unlike steel rebar, fiberglass rebar does not exhibit significant plastic deformation before failure, which can affect structural behavior under extreme loads.

- Lack of familiarity: Many construction professionals are less familiar with fiberglass rebar, which can lead to resistance in adoption or potential installation errors.

Best Practices for Using Bendable Fiberglass Rebar

To maximize the benefits of bendable fiberglass rebar while minimizing potential issues, consider the following best practices:

- Follow manufacturer guidelines: Adhere strictly to the manufacturer's recommendations for bending radii, techniques, and tools.

- Train personnel: Ensure that construction teams are properly trained in handling and installing fiberglass rebar, including bending techniques.

- Use appropriate design standards: Employ design standards specifically developed for fiberglass rebar, such as ACI 440.1R, when incorporating bent sections into structural designs.

- Quality control: Implement rigorous quality control measures to ensure that bent fiberglass rebar meets project specifications and maintains its structural integrity.

- Consider pre-bent options: For complex shapes or large-scale projects, consider using pre-bent fiberglass rebar sections to ensure consistency and quality.

Applications of Bent Fiberglass Rebar

Bent fiberglass rebar can be particularly useful in various construction applications, including:

- Curved structures: Architectural elements with curved designs, such as arches or domes.

- Marine environments: Coastal structures, seawalls, and bridge elements exposed to saltwater.

- Chemical plants: Areas with high chemical exposure where corrosion resistance is crucial.

- Transportation infrastructure: Highway barriers, bridge decks, and airport runways.

- Precast concrete elements: Custom-shaped precast concrete components for various applications.

Future Developments in Bendable Fiberglass Rebar

As the construction industry continues to embrace innovative materials, ongoing research and development efforts are focused on improving the bendability and overall performance of fiberglass rebar. Some areas of focus include:

- Enhanced resin systems: Development of new polymer matrices that offer improved flexibility without compromising strength.

- Hybrid reinforcement: Combining glass fibers with other materials to achieve a better balance of strength, flexibility, and cost-effectiveness.

- Advanced manufacturing techniques: Exploring new production methods that allow for more complex pre-bent shapes and improved overall performance.

- Standardization: Continued efforts to develop and refine industry standards for the design and use of bent fiberglass rebar in various applications.

Conclusion

Fiberglass rebar offers a promising alternative to traditional steel reinforcement, particularly in corrosive environments or applications requiring non-conductive materials. While it can be bent to some degree, it's crucial to understand its limitations and follow proper techniques to maintain its structural integrity. As the construction industry continues to evolve, the use of bendable fiberglass rebar is likely to increase, driven by its unique properties and ongoing advancements in material science.

By carefully considering the advantages, limitations, and best practices associated with bendable fiberglass rebar, engineers and construction professionals can make informed decisions about its use in various projects, potentially leading to more durable, efficient, and innovative structures.

FAQs

- Can fiberglass rebar be bent on-site?

Yes, but with limitations. Follow manufacturer guidelines and use proper tools to avoid damage. - Is bent fiberglass rebar as strong as straight sections?

Properly bent fiberglass rebar maintains most of its strength, but excessive bending can weaken it. - What's the minimum bend radius for fiberglass rebar?

It varies by product. Always consult the manufacturer's specifications for accurate information. - Can fiberglass rebar be re-bent after initial shaping?

Re-bending is not recommended as it can significantly weaken the material. - Is special training required to bend fiberglass rebar?

Yes, proper training is essential to ensure correct bending techniques and maintain structural integrity.