In the ever-evolving world of construction and engineering, innovative materials are constantly being developed to meet the growing demands of safety, durability, and sustainability. One such material that has gained significant traction in recent years is Chemgrate Fiberglass Grating. This revolutionary product offers a unique combination of strength, corrosion resistance, and environmental friendliness, making it an ideal choice for a wide range of applications across various industries.

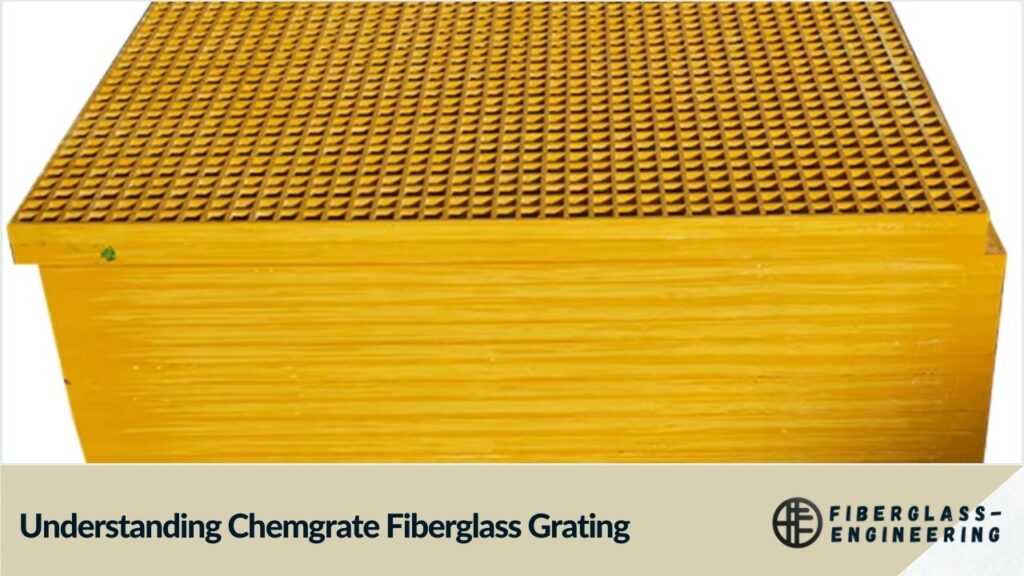

Understanding Chemgrate Fiberglass Grating

Chemgrate Fiberglass Grating is a high-performance composite material manufactured using a specialized molding process. It consists of fiberglass reinforcements embedded in a thermosetting resin matrix, resulting in a lightweight yet incredibly strong product. The grating is designed with a unique square mesh pattern, providing bidirectional strength and superior load-bearing capabilities.

One of the key advantages of Chemgrate Fiberglass Grating is its exceptional corrosion resistance. Unlike traditional metal gratings, which are prone to rust and degradation in harsh environments, Chemgrate remains unaffected by a wide range of chemicals, saltwater, and other corrosive substances. This makes it particularly suitable for use in marine environments, chemical processing plants, and wastewater treatment facilities.

Applications and Industries

The versatility of Chemgrate Fiberglass Grating has led to its adoption across numerous industries and applications. Some of the most common uses include:

- Industrial Platforms and Walkways: In manufacturing facilities and processing plants, Chemgrate provides a safe and durable walking surface that can withstand heavy foot traffic and equipment loads.

- Marine Structures: Docks, piers, and offshore platforms benefit from the corrosion-resistant properties of Chemgrate, ensuring longevity in saltwater environments.

- Chemical Processing: The grating's resistance to a wide range of chemicals makes it ideal for use in areas exposed to harsh substances and fumes.

- Water Treatment Facilities: Chemgrate's durability and resistance to bacteria and algae growth make it an excellent choice for water and wastewater treatment plants.

- Architectural Applications: The aesthetic appeal and customizable nature of Chemgrate allow for its use in various architectural designs, including facades and decorative elements.

Key Features and Benefits

Chemgrate Fiberglass Grating offers a host of advantages that set it apart from traditional grating materials:

- Lightweight Construction: Chemgrate is significantly lighter than steel or aluminum gratings, making it easier to transport, install, and maintain. This feature also reduces the overall load on supporting structures.

- High Strength-to-Weight Ratio: Despite its lightweight nature, Chemgrate boasts impressive strength properties, capable of supporting substantial loads without deformation.

- Fire Resistance: Chemgrate is manufactured with fire-retardant resins, meeting or exceeding industry standards for flame spread and smoke generation.

- Non-Conductive: The non-metallic composition of Chemgrate makes it electrically non-conductive, enhancing safety in environments where electrical hazards are a concern.

- Low Maintenance: The corrosion-resistant properties of Chemgrate eliminate the need for frequent painting or coating, reducing long-term maintenance costs.

- Customization Options: Chemgrate can be manufactured in various colors, sizes, and patterns to suit specific project requirements and aesthetic preferences.

Environmental Benefits

In an era where sustainability is paramount, Chemgrate Fiberglass Grating offers several environmental advantages:

- Long Lifespan: The durability and corrosion resistance of Chemgrate result in a longer service life compared to traditional materials, reducing the need for frequent replacements and conserving resources.

- Energy Efficiency: The lightweight nature of Chemgrate reduces transportation-related energy consumption and emissions.

- Recyclability: At the end of its useful life, Chemgrate can be recycled and repurposed, minimizing waste and supporting circular economy principles.

- Low VOC Emissions: The manufacturing process of Chemgrate produces minimal volatile organic compound (VOC) emissions, contributing to better air quality.

Installation and Maintenance

Installing Chemgrate Fiberglass Grating is a straightforward process that can be accomplished with standard tools and equipment. The lightweight nature of the material allows for easier handling and positioning, reducing installation time and labor costs. Chemgrate panels can be easily cut and shaped on-site to accommodate various layouts and obstacles.

Maintenance of Chemgrate is minimal, typically requiring only periodic cleaning to remove dirt and debris. Unlike metal gratings, there is no need for regular painting or application of protective coatings. In the event of damage, individual panels can be easily replaced without disrupting the entire installation.

Safety Considerations

Safety is a paramount concern in any construction or industrial setting, and Chemgrate Fiberglass Grating addresses this issue through several key features:

- Slip Resistance: The surface of Chemgrate is designed with a textured finish that provides excellent slip resistance, even in wet or oily conditions.

- Fire Performance: As mentioned earlier, Chemgrate is manufactured with fire-retardant resins, meeting stringent fire safety standards.

- Load Capacity: Chemgrate is engineered to support substantial loads, ensuring a safe walking and working surface for personnel and equipment.

- Chemical Resistance: The material's resistance to a wide range of chemicals reduces the risk of degradation and failure in harsh environments.

Cost-Effectiveness

While the initial cost of Chemgrate Fiberglass Grating may be higher than some traditional materials, its long-term cost-effectiveness is significant. Factors contributing to its economic benefits include:

- Reduced Maintenance Costs: The corrosion-resistant nature of Chemgrate eliminates the need for frequent painting or replacement, resulting in lower maintenance expenses over time.

- Extended Lifespan: The durability of Chemgrate translates to a longer service life, reducing the frequency of replacements and associated costs.

- Lower Installation Costs: The lightweight nature of Chemgrate can lead to reduced installation time and labor costs, particularly in large-scale projects.

- Energy Savings: In applications where weight is a critical factor, such as offshore platforms or elevated structures, the use of lightweight Chemgrate can result in energy savings through reduced structural requirements.

Future Developments and Innovations

As the demand for sustainable and high-performance materials continues to grow, ongoing research and development efforts are focused on further enhancing the properties of Chemgrate Fiberglass Grating. Some areas of innovation include:

- Advanced Resin Systems: Development of new resin formulations to improve fire resistance, chemical resistance, and overall durability.

- Nanotechnology Integration: Incorporation of nanomaterials to enhance specific properties such as strength, UV resistance, and antimicrobial capabilities.

- Smart Grating Systems: Integration of sensors and monitoring technologies to provide real-time data on structural integrity and environmental conditions.

- Biodegradable Options: Exploration of bio-based resins and fibers to create more environmentally friendly grating solutions.

Conclusion

Chemgrate Fiberglass Grating represents a significant advancement in construction and engineering materials. Its unique combination of strength, durability, and environmental benefits make it an attractive option for a wide range of applications across various industries. As sustainability continues to be a driving force in the construction sector, materials like Chemgrate are poised to play an increasingly important role in shaping the built environment of the future.

By choosing Chemgrate Fiberglass Grating, engineers, architects, and project managers can ensure they are utilizing a cutting-edge material that not only meets the stringent performance requirements of modern construction but also aligns with the growing emphasis on environmental responsibility and long-term cost-effectiveness.

FAQs

- What is Chemgrate Fiberglass Grating?

Chemgrate is a high-performance composite material made of fiberglass reinforcements in a resin matrix, offering superior strength and corrosion resistance. - How long does Chemgrate Fiberglass Grating last?

With proper installation and maintenance, Chemgrate can last for several decades, significantly outlasting traditional metal gratings in corrosive environments. - Is Chemgrate Fiberglass Grating environmentally friendly?

Yes, Chemgrate is recyclable, has a long lifespan, and its production process generates minimal VOC emissions, making it an environmentally conscious choice. - Can Chemgrate Fiberglass Grating be customized?

Absolutely. Chemgrate can be manufactured in various colors, sizes, and patterns to meet specific project requirements and aesthetic preferences. - Is Chemgrate Fiberglass Grating fire-resistant?

Yes, Chemgrate is manufactured with fire-retardant resins, meeting or exceeding industry standards for flame spread and smoke generation.