In the world of construction and engineering, the choice of materials can significantly impact the success and longevity of a project. Two popular options that often come head-to-head are fiberglass I beams and steel beams. This article will delve into the characteristics, advantages, and limitations of both materials, helping you make an informed decision for your next project.

Understanding Fiberglass I Beams

Fiberglass I beams are a relatively new addition to the construction industry, but they have quickly gained popularity due to their unique properties. These beams are manufactured by reinforcing a plastic resin with glass fibers, resulting in a solid, lightweight material with impressive strength-to-weight ratio.

Composition and Manufacturing

The production of fiberglass I beams involves a process called pultrusion. This method allows for the creation of continuous lengths of fiberglass reinforced plastic (FRP) with consistent cross-sections. The result is a beam that mimics the shape of traditional steel I beams but with the added benefits of fiberglass.

Key Advantages

- Corrosion Resistance: One of the most significant advantages of fiberglass I beams is their exceptional resistance to corrosion. Unlike steel, fiberglass does not rust or deteriorate when exposed to moisture, chemicals, or saltwater environments.

- Lightweight: Fiberglass I beams are significantly lighter than their steel counterparts, weighing approximately 75% less. This characteristic makes them easier to transport, handle, and install, potentially reducing labor costs and installation time.

- Non-Conductive: Fiberglass is an excellent electrical insulator, making it ideal for use in environments where electrical conductivity could pose a safety risk.

- Low Maintenance: Due to their corrosion resistance, fiberglass I beams require minimal maintenance over their lifetime, eliminating the need for regular painting or rust prevention treatments.

Limitations

While fiberglass I beams offer numerous advantages, they do have some limitations:

- Lower Strength: Although strong for their weight, fiberglass I beams generally have lower absolute strength compared to steel beams of the same size.

- Higher Initial Cost: The production process for fiberglass I beams is more complex than that of steel, resulting in a higher upfront cost.

- Temperature Sensitivity: Extreme temperatures can affect the performance of fiberglass I beams, potentially leading to expansion or contraction.

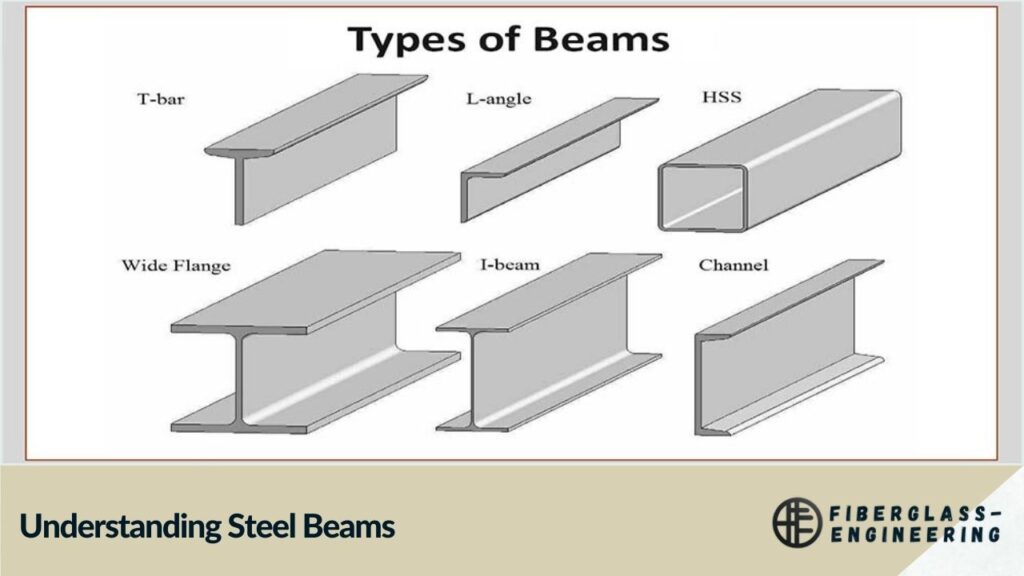

Understanding Steel Beams

Steel beams have been a staple in construction for centuries, known for their strength and versatility. They are made from an alloy of iron and carbon, often with additional elements to enhance specific properties.

Composition and Manufacturing

Steel beams are typically produced through a hot-rolling process, where heated steel is passed through a series of rollers to achieve the desired shape and size. This process allows for the creation of various beam profiles, including the popular I-beam shape.

Key Advantages

- High Strength: Steel beams are renowned for their exceptional strength and ability to withstand high levels of stress. This makes them ideal for large-scale construction projects like bridges and skyscrapers.

- Cost-Effective: Despite fluctuations in steel prices, the production process for steel beams is generally less expensive than that of fiberglass, making them more cost-effective for many projects.

- Versatility: Steel can be easily welded, cut, and shaped on-site, offering greater flexibility during construction and modifications.

- Fire Resistance: Steel has inherent fire-resistant properties, which can be further enhanced with fireproofing treatments.

Limitations

Steel beams, despite their widespread use, do have some drawbacks:

- Corrosion Susceptibility: Steel's primary weakness is its vulnerability to corrosion, especially in humid or coastal environments. This can lead to structural weakening over time if not properly maintained.

- Weight: Steel beams are significantly heavier than fiberglass, which can increase transportation costs and require more substantial support structures.

- Conductivity: Steel is an excellent conductor of electricity and heat, which can be a disadvantage in certain applications where insulation is required.

Comparing Performance in Different Applications

The choice between fiberglass I beams and steel beams often depends on the specific requirements of a project. Let's examine how these materials perform in various applications:

Marine Environments

In coastal areas or marine applications, fiberglass I beams have a clear advantage. Their corrosion resistance makes them ideal for structures exposed to saltwater or high humidity. Steel beams, on the other hand, would require extensive and ongoing corrosion protection measures.

High-Rise Buildings

For tall buildings and skyscrapers, steel beams remain the preferred choice. Their superior strength and ability to withstand high loads make them essential for these large-scale projects. Fiberglass I beams, while strong for their weight, are not typically used in such applications due to their lower absolute strength.

Chemical Plants and Industrial Facilities

In environments where exposure to corrosive chemicals is a concern, fiberglass I beams offer significant benefits. Their resistance to a wide range of chemicals makes them suitable for use in chemical plants, water treatment facilities, and other industrial settings where steel might quickly degrade.

Electrical Installations

For projects requiring electrical insulation, such as in power plants or substations, fiberglass I beams are the superior option. Their non-conductive nature eliminates the risk of electrical accidents, making them safer and more suitable for these specialized applications.

Temporary Structures

In situations where temporary structures are needed, the lightweight nature of fiberglass I beams can be advantageous. They are easier to transport and erect, making them ideal for temporary bridges, scaffolding, or emergency shelters.

Cost Considerations

When comparing fiberglass I beams and steel beams, it's essential to consider both initial and long-term costs:

Initial Costs

Steel beams generally have a lower upfront cost due to their simpler manufacturing process and widespread availability. Fiberglass I beams, being a more specialized product, often come with a higher initial price tag.

Long-Term Costs

Over time, the cost equation can shift in favor of fiberglass I beams. Their low maintenance requirements and resistance to corrosion can result in significant savings on upkeep, repairs, and replacements. In contrast, steel beams may require regular painting, rust prevention treatments, and potentially earlier replacement in harsh environments.

Life-Cycle Analysis

When conducting a life-cycle cost analysis, it's crucial to consider factors such as:

- Installation costs (including equipment and labor)

- Maintenance requirements

- Expected lifespan in the intended environment

- Potential for recycling or reuse at end-of-life

In many cases, especially in corrosive environments or applications requiring minimal maintenance, the long-term cost benefits of fiberglass I beams can outweigh their higher initial investment.

Environmental Considerations

As sustainability becomes an increasingly important factor in construction, it's worth examining the environmental impact of both materials:

Steel Beams

Steel has the advantage of being 100% recyclable, and many steel beams contain a significant percentage of recycled content. However, the production of steel is energy-intensive and generates substantial CO2 emissions.

Fiberglass I Beams

While not as easily recyclable as steel, fiberglass I beams have other environmental benefits. Their longer lifespan in certain applications means less frequent replacement and reduced resource consumption over time. Additionally, their lightweight nature can lead to reduced transportation emissions.

Future Trends and Innovations

Both fiberglass and steel industries continue to innovate, seeking to improve their products' performance and sustainability:

Advancements in Fiberglass Technology

Research is ongoing to enhance the strength and fire resistance of fiberglass composites. New resin formulations and fiber arrangements promise to expand the potential applications of fiberglass I beams.

Steel Industry Innovations

The steel industry is focusing on developing stronger, lighter steel alloys and improving the energy efficiency of production processes. Efforts are also being made to reduce the carbon footprint of steel manufacturing.

Conclusion

The choice between fiberglass I beams and steel beams is not always straightforward. Each material has its strengths and weaknesses, making them suitable for different applications. Fiberglass I beams excel in corrosive environments, lightweight applications, and situations requiring electrical insulation. Steel beams remain the go-to choice for high-strength applications and large-scale construction projects.

Ultimately, the decision should be based on a careful analysis of the specific project requirements, environmental conditions, long-term cost considerations, and sustainability goals. As both materials continue to evolve, we can expect to see their roles in construction and engineering continue to expand and complement each other.

FAQs

- Are fiberglass I beams stronger than steel?

No, steel beams generally have higher absolute strength, but fiberglass I beams have a better strength-to-weight ratio. - Which is more cost-effective, fiberglass or steel beams?

Steel beams typically have lower initial costs, but fiberglass I beams may be more cost-effective long-term due to lower maintenance requirements. - Can fiberglass I beams be used in high-rise buildings?

Generally no, high-rise buildings primarily use steel beams due to their superior strength and load-bearing capacity. - Are fiberglass I beams fire-resistant?

Fiberglass I beams can be manufactured with fire-retardant properties, but steel naturally has better fire resistance. - Which beam type is better for marine environments?

Fiberglass I beams are superior in marine environments due to their excellent corrosion resistance.