Fiberglass systems have become an integral part of various industries, offering innovative solutions that combine durability, versatility, and cost-effectiveness. These systems, composed of glass fibers embedded in a resin matrix, provide a range of benefits that make them superior to traditional materials in many applications.

Understanding Fiberglass Systems

Fiberglass systems encompass a wide array of products, including tanks, pipes, and structural components. The unique properties of fiberglass make it an ideal material for numerous industrial and commercial applications. Its strength-to-weight ratio, corrosion resistance, and thermal insulation properties set it apart from conventional materials like steel, concrete, and wood.

The manufacturing process of fiberglass systems involves combining glass fibers with a polymer resin, typically polyester or vinyl ester. This combination results in a material that is both lightweight and incredibly strong. The versatility of fiberglass allows for the creation of custom shapes and sizes, making it suitable for a diverse range of applications across various industries.

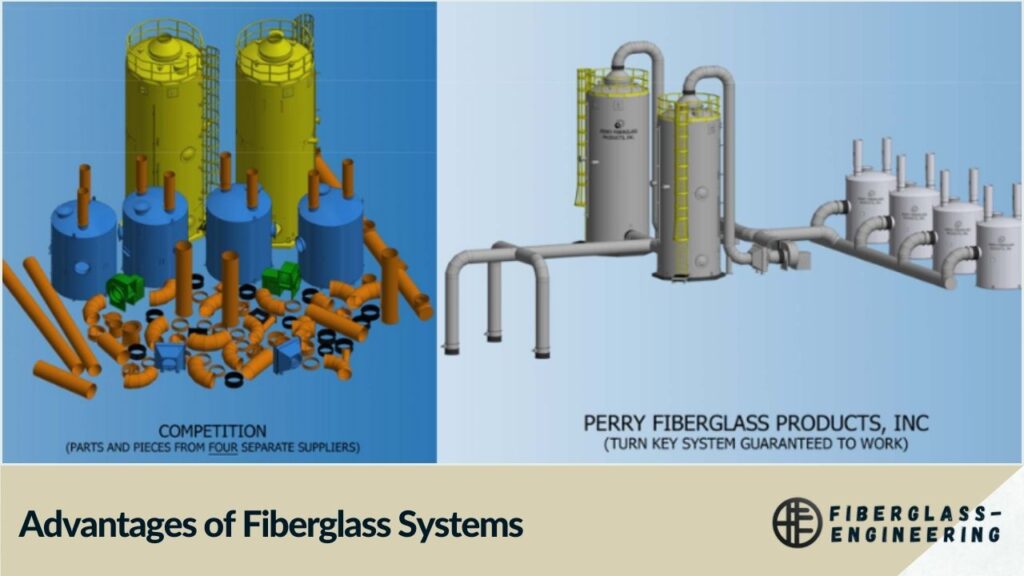

Advantages of Fiberglass Systems

Fiberglass systems offer numerous advantages that make them an attractive choice for many industries:

Corrosion Resistance: One of the most significant benefits of fiberglass systems is their exceptional resistance to corrosion. Unlike metal alternatives, fiberglass does not rust or deteriorate when exposed to harsh chemicals, saltwater, or other corrosive environments. This property makes fiberglass systems ideal for use in chemical processing plants, wastewater treatment facilities, and marine applications.

Durability: Fiberglass systems are known for their long-lasting performance. They can withstand extreme temperatures, UV radiation, and physical stress without compromising their structural integrity. This durability translates to reduced maintenance costs and extended service life, making fiberglass systems a cost-effective choice in the long run.

Lightweight: The low weight of fiberglass systems offers significant advantages in terms of transportation, installation, and structural load requirements. This characteristic is particularly beneficial in applications where weight is a critical factor, such as in offshore platforms or in retrofitting existing structures.

Thermal Insulation: Fiberglass systems provide excellent thermal insulation properties, making them suitable for applications where temperature control is crucial. This feature is particularly valuable in the oil and gas industry, where maintaining consistent temperatures in pipelines and storage tanks is essential.

Customizability: The flexibility of fiberglass allows for the creation of custom-designed systems tailored to specific requirements. This adaptability enables engineers to develop innovative solutions for complex industrial challenges.

Applications of Fiberglass Systems

Fiberglass systems find applications across a wide range of industries, each benefiting from the material's unique properties:

Chemical Processing: In the chemical industry, fiberglass tanks and pipes are used to store and transport corrosive substances safely. The material's resistance to chemicals ensures the integrity of the system and prevents contamination.

Water and Wastewater Treatment: Fiberglass systems are extensively used in water treatment plants for storage tanks, pipes, and filtration systems. Their corrosion resistance and durability make them ideal for handling both potable water and wastewater.

Oil and Gas: The oil and gas sector relies heavily on fiberglass systems for various applications, including offshore platforms, pipelines, and storage tanks. The material's ability to withstand harsh environments and corrosive substances makes it an excellent choice for this industry.

Pulp and Paper: Fiberglass systems are used in pulp and paper mills for chemical storage, piping, and process equipment. Their resistance to acids and other chemicals used in paper production ensures long-term reliability.

Marine and Offshore: The marine industry utilizes fiberglass systems for boat hulls, decking, and various components due to their lightweight nature and resistance to saltwater corrosion.

Construction: In the construction industry, fiberglass systems are used for reinforcing concrete, creating decorative elements, and manufacturing durable building materials.

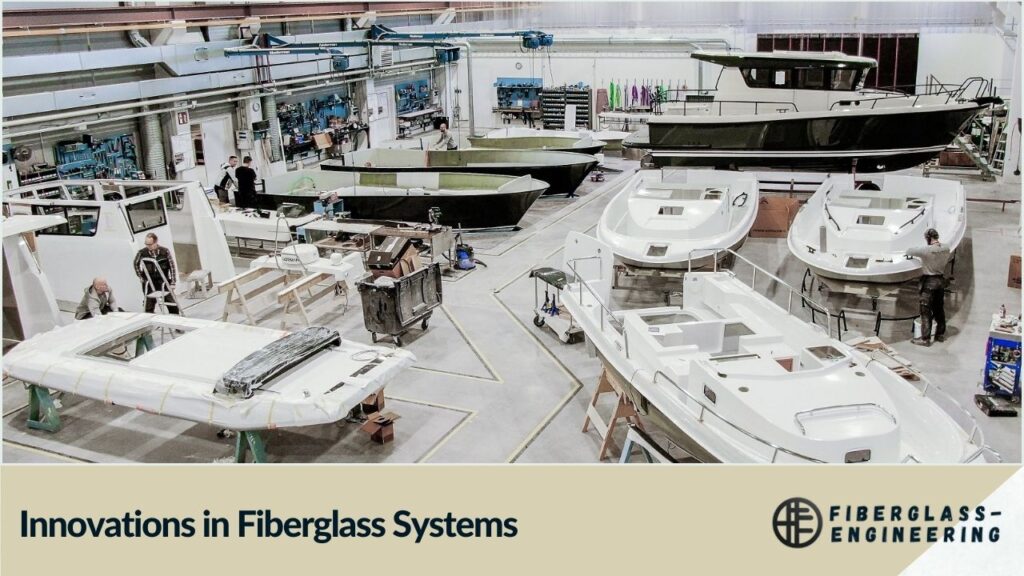

Innovations in Fiberglass Systems

The field of fiberglass systems continues to evolve, with ongoing research and development leading to new innovations:

Advanced Composites: Researchers are developing new composite materials that combine fiberglass with other materials to enhance specific properties, such as impact resistance or fire retardancy.

Smart Fiberglass Systems: Integration of sensors and monitoring technologies into fiberglass systems is enabling real-time performance tracking and predictive maintenance, enhancing the overall efficiency and safety of industrial operations.

Sustainable Manufacturing: Efforts are being made to develop more environmentally friendly manufacturing processes for fiberglass systems, including the use of recycled materials and bio-based resins.

Considerations for Implementing Fiberglass Systems

While fiberglass systems offer numerous advantages, there are several factors to consider when implementing them:

Design and Engineering: Proper design and engineering are crucial for maximizing the benefits of fiberglass systems. Factors such as load requirements, chemical exposure, and environmental conditions must be carefully considered.

Installation: While generally easier to install than traditional materials, fiberglass systems require specialized knowledge and techniques for proper installation to ensure optimal performance.

Regulatory Compliance: Depending on the application and industry, fiberglass systems may need to meet specific regulatory standards and certifications.

Life Cycle Cost: Although the initial cost of fiberglass systems may be higher than some traditional materials, their long-term durability and low maintenance requirements often result in a lower overall life cycle cost.

Future Outlook

The future of fiberglass systems looks promising, with continued growth expected across various industries. As environmental concerns and the need for sustainable solutions increase, the demand for durable, corrosion-resistant, and energy-efficient materials like fiberglass is likely to grow.

Advancements in manufacturing technologies and material science are expected to further enhance the properties of fiberglass systems, opening up new applications and markets. The integration of smart technologies and the development of more sustainable production methods will likely drive innovation in the field.

In conclusion, fiberglass systems represent a versatile and robust solution for numerous industrial challenges. Their unique combination of properties, including corrosion resistance, durability, and customizability, makes them an attractive choice for a wide range of applications. As industries continue to seek more efficient and sustainable solutions, fiberglass systems are poised to play an increasingly important role in shaping the future of industrial infrastructure and technology.

FAQs

- What are the main advantages of fiberglass systems?

Fiberglass systems offer corrosion resistance, durability, lightweight properties, and customizability. They are ideal for various industrial applications due to their versatility and long-term cost-effectiveness. - In which industries are fiberglass systems commonly used?

Fiberglass systems are widely used in chemical processing, water treatment, oil and gas, pulp and paper, marine, and construction industries. Their unique properties make them suitable for diverse applications across these sectors. - How do fiberglass systems compare to traditional materials like steel or concrete?

Fiberglass systems are generally more corrosion-resistant, lighter, and easier to install than steel or concrete. While initial costs may be higher, they often provide better long-term value due to lower maintenance requirements and extended service life. - Are fiberglass systems environmentally friendly?

Fiberglass systems can be considered environmentally friendly due to their long lifespan and low maintenance requirements. Ongoing research is focused on developing more sustainable manufacturing processes and incorporating recycled materials. - What innovations are emerging in fiberglass systems?

Emerging innovations include advanced composites with enhanced properties, smart fiberglass systems with integrated sensors, and more sustainable manufacturing processes. These developments are expanding the potential applications and benefits of fiberglass systems.