In the world of composite materials, two terms often come up: FRP and fiberglass. While these terms are sometimes used interchangeably, there are important distinctions between them that are crucial for engineers, manufacturers, and consumers to understand. This article will delve into the differences between FRP and fiberglass, their properties, applications, and why it matters.

What is Fiberglass?

Fiberglass, short for glass fiber reinforced plastic, is a composite material made by spinning molten glass into fine fibers. These fibers are then combined with a polymer resin to create a strong, lightweight material. The resulting product is known for its durability, flexibility, and resistance to corrosion.

Fiberglass has been used in various industries since its development in the 1930s. It's commonly found in products ranging from boat hulls and automotive parts to building insulation and sporting goods. The versatility of fiberglass comes from its unique combination of properties:

- High strength-to-weight ratio

- Excellent insulation properties

- Resistance to water and chemicals

- Dimensional stability

- Low thermal conductivity

Understanding FRP

FRP stands for Fiber Reinforced Polymer (or Plastic). It's a broader term that encompasses a variety of composite materials, including fiberglass. FRP refers to any polymer matrix reinforced with fibers, which can include glass fibers (as in fiberglass), carbon fibers, aramid fibers, or even natural fibers like hemp or flax.

The key components of FRP are:

- The matrix: Usually a thermoset polymer like polyester, vinyl ester, or epoxy resin

- The reinforcement: Fibers that provide strength and stiffness

- Additives: Materials added to modify specific properties

FRP materials can be tailored to meet specific performance requirements by adjusting the type and amount of fibers, the matrix material, and any additives used. This flexibility makes FRP suitable for a wide range of applications across various industries.

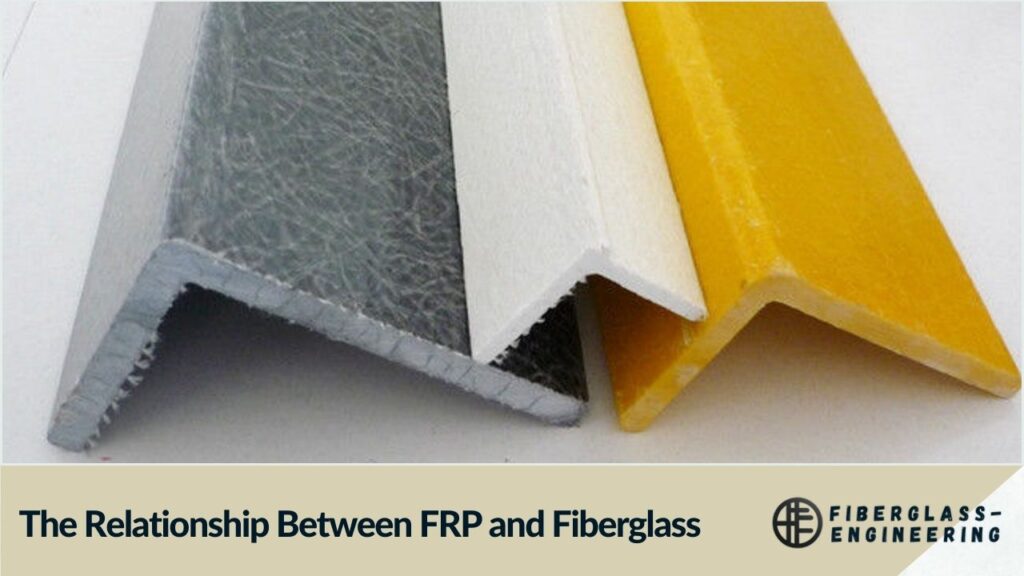

The Relationship Between FRP and Fiberglass

To understand the relationship between FRP and fiberglass, it's helpful to think of it this way: All fiberglass is a type of FRP, but not all FRP is fiberglass. Fiberglass specifically refers to glass fiber reinforced polymers, while FRP can include composites made with other types of fibers.

This distinction is important because different fiber types can impart different properties to the final composite:

- Glass fibers (fiberglass) offer a good balance of strength, weight, and cost

- Carbon fibers provide higher strength and stiffness but at a higher cost

- Aramid fibers offer excellent impact resistance and are commonly used in ballistic applications

- Natural fibers can provide more environmentally friendly options

Properties and Advantages of FRP and Fiberglass

Both FRP and fiberglass offer several advantages over traditional materials like metal, wood, or concrete:

- Lightweight: FRP and fiberglass have high strength-to-weight ratios, making them ideal for applications where weight reduction is crucial.

- Corrosion Resistance: Unlike metals, these materials don't rust or corrode, leading to longer lifespans and reduced maintenance costs.

- Design Flexibility: FRP and fiberglass can be molded into complex shapes, allowing for greater design freedom.

- Electrical Insulation: These materials are excellent electrical insulators, making them suitable for use in electrical and electronic applications.

- Thermal Insulation: FRP and fiberglass have low thermal conductivity, making them effective insulators.

- Durability: They resist weathering, UV radiation, and many chemicals, contributing to their long-term performance.

Applications of FRP and Fiberglass

The versatility of FRP and fiberglass has led to their use in a wide range of industries and applications:

Construction and Infrastructure

FRP and fiberglass are increasingly used in construction for their durability and low maintenance requirements. Applications include:

- Bridge decks and structural components

- Reinforcement bars (rebar) for concrete

- Architectural panels and cladding

- Cooling towers and chemical storage tanks

Transportation

The lightweight nature of these materials makes them ideal for transportation applications:

- Automotive body panels and components

- Aircraft interiors and structural parts

- Marine vessel hulls and decks

- Rail car bodies and components

Renewable Energy

FRP and fiberglass play a crucial role in the renewable energy sector:

- Wind turbine blades

- Solar panel frames and supports

- Hydroelectric turbine components

Industrial and Chemical Processing

The corrosion resistance of these materials is particularly valuable in industrial settings:

- Pipes and tanks for chemical processing

- Offshore oil and gas platforms

- Industrial flooring and gratings

Choosing Between FRP and Fiberglass

When deciding between FRP and fiberglass for a specific application, several factors should be considered:

- Performance Requirements: Consider the specific strength, stiffness, and other properties needed for your application.

- Environmental Conditions: Assess the exposure to chemicals, UV radiation, and other environmental factors.

- Cost Considerations: Generally, fiberglass is more cost-effective than advanced FRP composites using carbon or aramid fibers.

- Weight Restrictions: If weight is a critical factor, advanced FRP composites might be preferable to fiberglass.

- Manufacturing Process: Some manufacturing methods may be better suited to certain types of FRP or fiberglass.

Future Trends in FRP and Fiberglass

As technology advances, we can expect to see continued innovation in the field of composite materials:

- Improved Recycling Methods: Developing better ways to recycle FRP and fiberglass to address environmental concerns.

- Bio-based Resins: Increasing use of resins derived from renewable resources to reduce environmental impact.

- Hybrid Composites: Combining different types of fibers to create composites with optimized properties.

- Nanocomposites: Incorporating nanoparticles into the matrix to enhance specific properties.

Conclusion

While the terms FRP and fiberglass are often used interchangeably, understanding their differences is crucial for making informed decisions in material selection. Fiberglass, with its specific use of glass fibers, remains a popular and cost-effective option for many applications. However, the broader category of FRP offers even more possibilities for tailoring material properties to specific needs.

As we continue to push the boundaries of material science, FRP and fiberglass will undoubtedly play an increasingly important role in shaping the future of various industries. Their unique combination of strength, lightweight, and versatility makes them indispensable materials in our modern world.

FAQs

- What is the main difference between FRP and fiberglass?

FRP is a broader term that includes any fiber-reinforced polymer, while fiberglass specifically refers to glass fiber-reinforced polymers. - Is FRP stronger than fiberglass?

It depends on the specific composition; some FRP using carbon fibers can be stronger than fiberglass, but fiberglass itself is a type of FRP. - Which is more cost-effective, FRP or fiberglass?

Generally, fiberglass is more cost-effective than advanced FRP composites using carbon or aramid fibers. - Can FRP and fiberglass be recycled?

Yes, both can be recycled, but the process is complex and not as straightforward as recycling metals or plastics. - Are FRP and fiberglass environmentally friendly?

While they offer durability and energy efficiency benefits, their production and disposal can have environmental impacts. Ongoing research aims to improve their sustainability.