Fiberglass rebar, also known as Glass Fiber Reinforced Polymer (GFRP) rebar, has become increasingly popular in construction due to its superior strength, lightweight properties, and corrosion resistance. However, cutting this material requires specific techniques and precautions to ensure safety and maintain the integrity of the rebar. This guide will provide you with detailed instructions on how to cut fiberglass rebar effectively and safely.

Understanding Fiberglass Rebar

Before diving into the cutting process, it's essential to understand the nature of fiberglass rebar. Fiberglass rebar is a composite material reinforced with glass fibers and bound together with synthetic resin. It's designed to replace traditional steel rebar in various construction applications, especially in environments prone to corrosion.

The unique properties of fiberglass rebar include:

- High tensile strength

- Lightweight (about 25% the weight of steel rebar)

- Corrosion resistance

- Non-conductive

- Low thermal conductivity

These characteristics make fiberglass rebar an excellent choice for highways, bridges, marine structures, and other projects where durability and resistance to harsh environments are crucial.

Tools and Materials Needed

To cut fiberglass rebar properly, you'll need the following tools and materials:

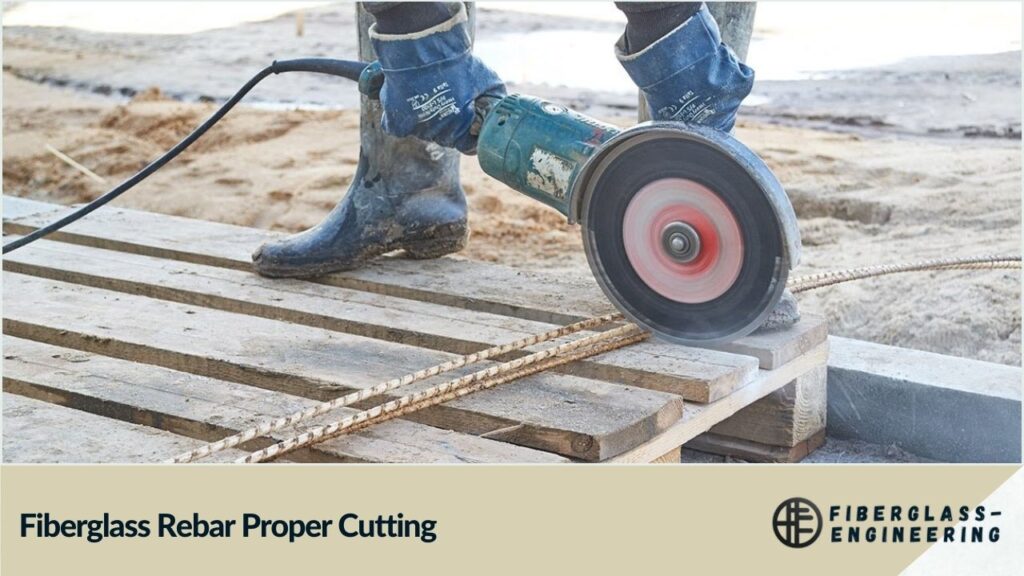

- Diamond blade saw or angle grinder: These are the preferred tools for cutting fiberglass rebar due to their precision and efficiency.

- Protective gear: Safety glasses, gloves, and a dust mask are essential to protect yourself from fiberglass particles and dust.

- Measuring tape and marker: For accurate measurements and marking cut points.

- Clamps or vise: To secure the rebar during cutting.

- Work surface: A stable, flat surface to work on.

Step-by-Step Guide to Cutting Fiberglass Rebar

1. Preparation

- Ensure your work area is well-ventilated to minimize the spread of fiberglass dust.

- Put on your protective gear, including safety glasses, gloves, and a dust mask.

- Measure and mark the cutting points on the fiberglass rebar using a measuring tape and marker.

- Secure the rebar to your work surface using clamps or a vise to prevent movement during cutting.

2. Setting Up the Cutting Tool

- If using a diamond blade saw, ensure the blade is appropriate for cutting fiberglass and is securely attached to the saw.

- For an angle grinder, attach a diamond cutting wheel designed for fiberglass materials.

- Check that your cutting tool is in good condition and operating correctly before proceeding.

3. Cutting Process

- Align the blade or cutting wheel with your marked cutting point.

- Start the tool and allow it to reach full speed before making contact with the rebar.

- Apply steady, moderate pressure as you guide the blade through the rebar. Avoid forcing the tool, as this can cause damage to both the rebar and the cutting tool.

- Move the blade or wheel slowly and consistently through the rebar to ensure a clean, straight cut.

- If necessary, rotate the rebar to complete the cut from all sides.

4. Finishing

- Once the cut is complete, turn off the cutting tool and allow it to come to a complete stop before setting it down.

- Inspect the cut end of the rebar for any rough edges or splinters.

- If needed, use a file or sandpaper to smooth out any imperfections on the cut end.

Safety Precautions and Best Practices

Cutting fiberglass rebar requires careful attention to safety. Here are some important precautions and best practices to follow:

- Always wear protective gear: This cannot be stressed enough. Fiberglass particles can be harmful if inhaled or if they come into contact with your skin or eyes.

- Work in a well-ventilated area: Proper ventilation helps disperse fiberglass dust and fumes from the cutting process.

- Secure the rebar properly: Ensure the rebar is firmly clamped or held in place to prevent slipping or movement during cutting.

- Maintain your tools: Regularly inspect and maintain your cutting tools to ensure they're in good working condition.

- Take breaks and clean up: Periodically stop to clean up fiberglass dust and debris from your work area.

- Proper disposal: Dispose of fiberglass waste according to local regulations, as it can be harmful to the environment if not handled correctly.

Advantages of Proper Cutting Techniques

Using the correct cutting techniques for fiberglass rebar offers several advantages:

- Precision: Proper cutting ensures accurate lengths and clean ends, which are crucial for construction projects.

- Safety: Following the right procedures minimizes the risk of injury and exposure to harmful fiberglass particles.

- Tool longevity: Correct cutting techniques help preserve the life of your cutting tools.

- Material integrity: Proper cutting maintains the structural integrity of the fiberglass rebar, ensuring it performs as intended in construction applications.

Common Mistakes to Avoid

When cutting fiberglass rebar, be aware of these common mistakes:

- Using inappropriate tools: Avoid using hacksaws or standard metal-cutting blades, as these can cause fraying and damage to the rebar.

- Applying too much pressure: Excessive force can lead to uneven cuts or even break the rebar.

- Neglecting safety gear: Always prioritize safety by wearing the appropriate protective equipment.

- Cutting in poorly ventilated areas: This can lead to the accumulation of harmful fiberglass dust.

- Rushing the cutting process: Take your time to ensure accurate and safe cuts.

Alternative Cutting Methods

While diamond blade saws and angle grinders are the most common tools for cutting fiberglass rebar, there are alternative methods for specific situations:

- Hydraulic cutters: These are ideal for large-scale projects requiring numerous cuts.

- Abrasive water jet cutting: This method uses high-pressure water mixed with abrasive particles and is suitable for precision cutting.

- Laser cutting: While less common, laser cutting can provide extremely precise cuts for specialized applications.

Each method has its advantages and is suited to different project scales and requirements. Always choose the method that best fits your specific needs and safety considerations.

Conclusion

Cutting fiberglass rebar correctly is crucial for ensuring the safety and success of your construction project. By following the steps and precautions outlined in this guide, you can effectively cut fiberglass rebar while maintaining its structural integrity and protecting yourself from potential hazards. Remember, the key to successful cutting lies in using the right tools, following proper techniques, and prioritizing safety at all times.

FAQs

- What's the best tool for cutting fiberglass rebar?

A diamond blade saw or angle grinder with a diamond cutting wheel is ideal for cutting fiberglass rebar. - Is it safe to cut fiberglass rebar without protective gear?

No, always wear safety glasses, gloves, and a dust mask to protect yourself from harmful fiberglass particles. - Can I use a regular metal-cutting blade to cut fiberglass rebar?

No, regular metal-cutting blades can cause fraying and damage. Use diamond blades designed for fiberglass. - How do I ensure a clean cut on fiberglass rebar?

Secure the rebar firmly, use a sharp diamond blade, and apply steady, moderate pressure while cutting slowly. - Is it necessary to smooth the cut ends of fiberglass rebar?

Yes, smoothing cut ends with a file or sandpaper helps prevent injury and ensures proper fitting in construction.

👉 Check this out: Fiberglass Shingles vs Asphalt Shingles: A Comprehensive Guide for Homeowners

👉 Relevant article: What Happens If You Inhale Fiberglass? A Comprehensive Guide to Health Impacts

📜 Must-reads: Fiberglass Tent Pole Repair: A Comprehensive Guide