Fiberglass rods are versatile materials used in various industries, from construction to sporting equipment manufacturing. However, cutting these durable rods can be challenging without the right tools and techniques. This guide will provide you with detailed instructions on how to cut fiberglass rods safely and effectively.

Essential Tools for Cutting Fiberglass Rods

Before you begin, gather the following tools:

- Fine-toothed saw: A saw with small, sharp teeth is crucial for cutting through fiberglass without causing excessive splintering.

- Safety equipment: Protect yourself with safety goggles, a dust mask, and gloves to prevent exposure to harmful fiberglass particles.

- Measuring tape: Accurate measurements are essential for precise cuts.

- Clamp or vise: Secure the rod firmly to prevent movement during cutting.

- Sandpaper: Use this to smooth the cut edges and remove any burrs.

- Lubricant: A cutting lubricant can help reduce friction and heat during the cutting process.

Preparing to Cut Fiberglass Rods

Proper preparation is key to achieving clean, accurate cuts:

- Measure and mark: Use your measuring tape to determine the desired length and mark the cutting point clearly on the rod.

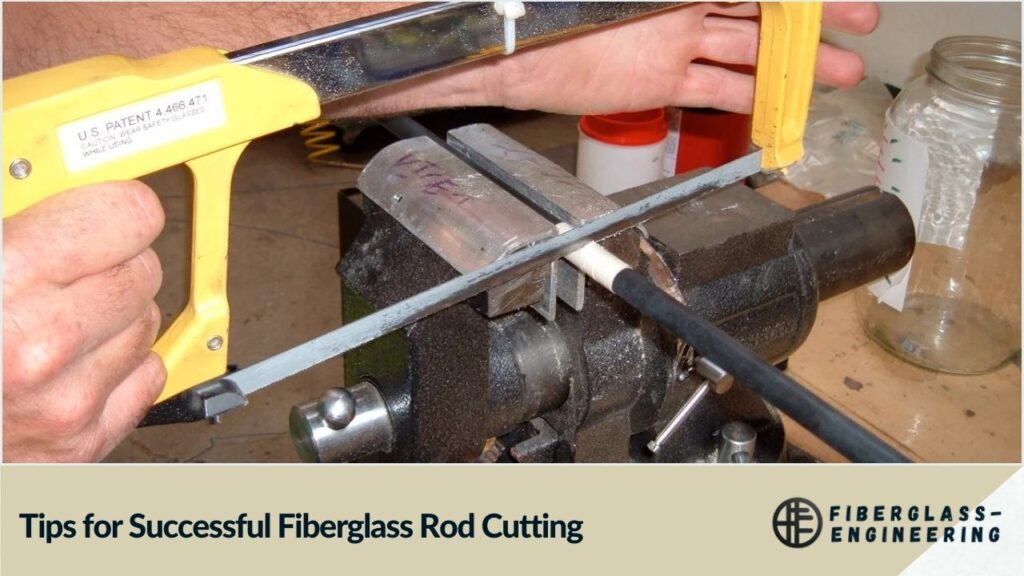

- Secure the rod: Place the fiberglass rod in a clamp or vise, ensuring it's firmly held in place. This step is crucial for safety and precision.

- Put on safety gear: Don your safety goggles, dust mask, and gloves before proceeding.

Cutting Techniques for Fiberglass Rods

Using a Fine-Toothed Saw

- Position the saw: Align the fine-toothed saw with your marked cutting line.

- Start cutting: Begin with gentle, even strokes to create a shallow groove along the cutting line.

- Maintain steady pressure: As you continue cutting, apply consistent pressure and let the saw do the work. Avoid forcing the blade through the material.

- Rotate the rod: If possible, rotate the rod as you cut to maintain an even cut around the circumference.

- Complete the cut: Continue sawing until you've cut through the entire rod.

Alternative Cutting Methods

While a fine-toothed saw is the most common tool, other methods can be effective:

- Rotary tool: A rotary tool with an abrasive cutting wheel can make quick, clean cuts on smaller diameter rods.

- Angle grinder: For larger rods, an angle grinder with a thin cutting disc can be efficient but requires more skill to control.

- Pipe cutter: A specialized fiberglass pipe cutter can provide clean, straight cuts on rods of various diameters.

Post-Cutting Procedures

After cutting, follow these steps to finish the job:

- Sand the edges: Use fine-grit sandpaper to smooth the cut edges, removing any burrs or rough spots.

- Clean up: Thoroughly clean your work area to remove any fiberglass dust or debris. Use a vacuum with a HEPA filter for best results.

- Inspect the cut: Check the cut for straightness and smoothness, making any necessary adjustments.

Tips for Successful Fiberglass Rod Cutting

- Use a cutting lubricant: Applying a lubricant to the saw blade can reduce friction and heat, resulting in smoother cuts.

- Take breaks: If cutting multiple rods, take regular breaks to avoid fatigue and maintain precision.

- Practice on scrap pieces: If you're new to cutting fiberglass, practice on scrap pieces to perfect your technique.

- Consider professional cutting: For large-scale projects or extremely precise cuts, consider having the rods cut professionally.

Safety Precautions

Working with fiberglass requires strict adherence to safety protocols:

- Ventilation: Always work in a well-ventilated area to minimize exposure to fiberglass particles.

- Skin protection: Wear long sleeves and pants to protect your skin from irritation.

- Eye safety: Safety goggles are non-negotiable when cutting fiberglass.

- Respiratory protection: Use a dust mask rated for fiberglass particles to protect your lungs.

- Clean-up: Shower and change clothes after working with fiberglass to remove any lingering particles.

Choosing the Right Fiberglass Rod

Selecting the appropriate fiberglass rod for your project is crucial:

- Diameter: Consider the load-bearing requirements and application when choosing rod diameter.

- Length: Determine the required length for your project, factoring in any necessary overlaps or joints.

- Resin system: Different resin systems offer varying properties such as chemical resistance or UV stability.

- Fiber orientation: The arrangement of fibers within the rod affects its strength and flexibility.

By understanding these factors, you can select a fiberglass rod that not only cuts well but also performs optimally in your specific application.

Environmental Considerations

When cutting fiberglass rods, be mindful of the environmental impact:

- Dust collection: Use a dust collection system to minimize the release of fiberglass particles into the environment.

- Proper disposal: Dispose of fiberglass waste according to local regulations, as it may require special handling.

- Recycling: Investigate recycling options for fiberglass scraps in your area to reduce waste.

Conclusion

Cutting fiberglass rods requires the right tools, techniques, and safety precautions. By following this comprehensive guide, you can achieve clean, precise cuts while protecting yourself and the environment. Remember to always prioritize safety and take your time to ensure the best results. With practice, you'll develop the skills needed to work confidently with fiberglass rods in various applications.

FAQs

- What's the best tool for cutting fiberglass rods?

A fine-toothed saw is generally the best tool. It provides clean cuts with minimal splintering. - Is it necessary to wear protective gear when cutting fiberglass?

Yes, always wear safety goggles, a dust mask, and gloves to protect against harmful fiberglass particles. - Can I use a regular wood saw to cut fiberglass rods?

It's not recommended. A saw designed for fiberglass or a fine-toothed metal saw works best. - How do I prevent splintering when cutting fiberglass rods?

Use a fine-toothed saw, apply even pressure, and consider using a cutting lubricant to reduce friction. - Should I sand the cut edges of fiberglass rods?

Yes, sanding the cut edges helps remove burrs and creates a smoother, safer finish.

👉 Check this out: Fiberglass Shingles vs Asphalt Shingles: A Comprehensive Guide for Homeowners

👉 Relevant article: What Happens If You Inhale Fiberglass? A Comprehensive Guide to Health Impacts

🔝 Top articles: How to Cut Fiberglass Rebar: A Comprehensive Guide