In the ever-evolving world of construction, the choice of reinforcement materials plays a crucial role in determining the strength, durability, and longevity of structures. While steel rebar has been the traditional go-to option for decades, pink bar fiberglass rebar has emerged as a compelling alternative. This article delves into the characteristics, advantages, and limitations of both materials, providing a comprehensive comparison to help engineers, contractors, and project managers make informed decisions.

Understanding Rebar Basics

Rebar, short for reinforcement bar, is an essential component in reinforced concrete structures. Its primary function is to provide tensile strength to concrete, which is naturally strong in compression but weak in tension. By incorporating rebar, concrete structures can withstand various loads and stresses, preventing cracking and failure.

Steel Rebar: The Traditional Choice

Steel rebar has been the industry standard for reinforcing concrete structures for over a century. Its widespread use can be attributed to several factors:

Strength and Durability: Steel rebar boasts exceptional strength, making it suitable for a wide range of construction projects, from residential buildings to massive infrastructure developments. Its high tensile strength allows it to withstand significant loads and stresses.

Ductility: One of the key advantages of steel rebar is its ductility. This property allows the material to deform plastically under stress without immediate failure, providing a safety margin in structural design.

Cost-Effectiveness: Steel rebar is generally more affordable than its fiberglass counterpart, making it an attractive option for budget-conscious projects.

Availability: Steel rebar is widely available and can be easily sourced in various sizes and grades, ensuring quick procurement for construction projects.

However, steel rebar is not without its drawbacks:

Corrosion Susceptibility: Perhaps the most significant limitation of steel rebar is its vulnerability to corrosion, especially in harsh environmental conditions or when exposed to de-icing salts. Corrosion can lead to expansion, cracking, and eventual structural deterioration.

Weight: Steel rebar is relatively heavy, which can increase transportation costs and make handling on-site more challenging.

Thermal Conductivity: Steel has high thermal conductivity, which can be problematic in structures subjected to extreme temperature fluctuations.

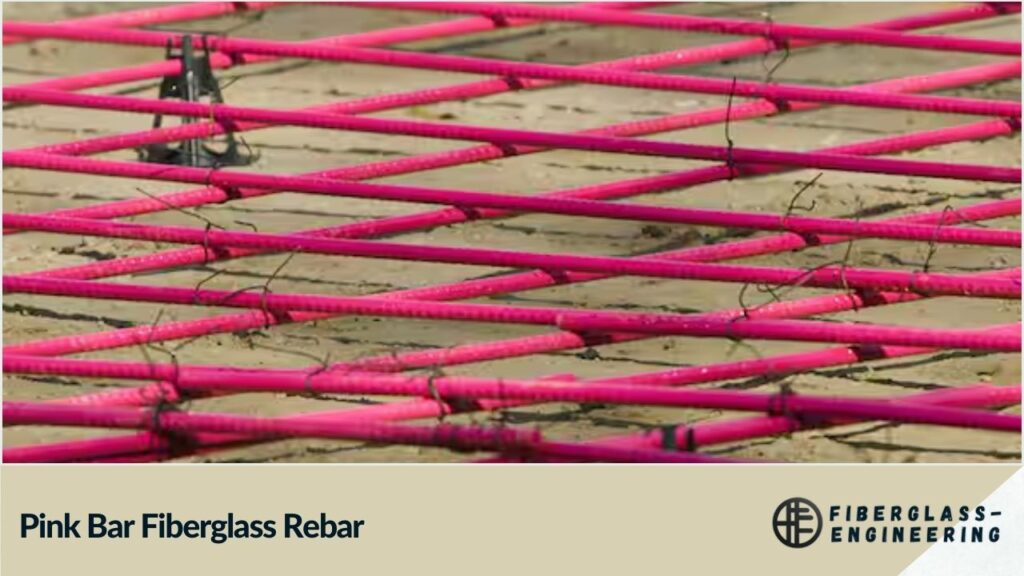

Pink Bar Fiberglass Rebar: The Innovative Alternative

Pink bar fiberglass rebar, also known as Glass Fiber Reinforced Polymer (GFRP) rebar, has gained traction in recent years as a viable alternative to steel. This innovative material offers several unique advantages:

Corrosion Resistance: The most significant advantage of pink bar fiberglass rebar is its immunity to corrosion. This property makes it ideal for structures exposed to harsh environments, such as marine applications, chemical plants, and areas with high salt exposure.

Lightweight: Fiberglass rebar is significantly lighter than steel, typically weighing about one-quarter of its steel counterpart. This characteristic simplifies transportation, handling, and installation processes.

High Tensile Strength: Despite its lightweight nature, pink bar fiberglass rebar boasts excellent tensile strength, often surpassing that of steel rebar.

Non-Conductive: Fiberglass rebar is electrically non-conductive, making it suitable for applications where electromagnetic interference is a concern, such as in hospital MRI rooms or near electrical installations.

Low Thermal Expansion: The material exhibits lower thermal expansion compared to steel, reducing the risk of thermal stress-induced cracking in concrete structures.

However, pink bar fiberglass rebar also has some limitations to consider:

Higher Initial Cost: The upfront cost of fiberglass rebar is generally higher than that of steel rebar, although this can be offset by long-term savings in maintenance and replacement costs.

Lower Modulus of Elasticity: Fiberglass rebar has a lower modulus of elasticity compared to steel, which means it may experience greater deflection under load. This characteristic requires careful consideration in structural design.

Brittle Behavior: Unlike steel, which exhibits ductile behavior, fiberglass rebar is more brittle and does not provide the same level of warning before failure.

Comparative Analysis

To better understand the differences between pink bar fiberglass rebar and steel rebar, let's examine some key factors:

Strength and Load-Bearing Capacity: While steel rebar is renowned for its high strength, pink bar fiberglass rebar offers comparable or even superior tensile strength in many cases. However, the lower modulus of elasticity of fiberglass rebar must be accounted for in structural calculations.

Durability and Longevity: In environments prone to corrosion, pink bar fiberglass rebar significantly outperforms steel rebar in terms of long-term durability. Structures reinforced with fiberglass rebar can potentially have a longer service life with reduced maintenance requirements.

Installation and Handling: The lightweight nature of fiberglass rebar makes it easier to transport and handle on-site, potentially reducing labor costs and improving worker safety. However, it requires more careful handling to prevent damage during installation.

Environmental Impact: Fiberglass rebar production generally has a lower carbon footprint compared to steel rebar manufacturing. Additionally, its corrosion resistance can lead to reduced concrete cover requirements, potentially decreasing overall material usage.

Cost Considerations: While the initial cost of pink bar fiberglass rebar is higher, it's essential to consider the total life-cycle cost of the structure. The reduced maintenance and replacement costs associated with fiberglass rebar can result in significant long-term savings, especially in corrosive environments.

Applications and Best Practices

The choice between pink bar fiberglass rebar and steel rebar ultimately depends on the specific requirements of each project. Here are some guidelines for their application:

Pink Bar Fiberglass Rebar: Ideal for structures exposed to corrosive environments, such as:

- Marine structures (seawalls, piers, bridges)

- Water treatment plants

- Chemical processing facilities

- Parking structures (especially in areas using de-icing salts)

- MRI rooms in hospitals

- Structures requiring non-magnetic properties

Steel Rebar: Remains the preferred choice for:

- High-rise buildings

- Heavy load-bearing structures

- Applications where ductility is crucial

- Projects with tight budgets and non-corrosive environments

Conclusion

Both pink bar fiberglass rebar and steel rebar have their place in modern construction. While steel rebar continues to be the go-to choice for many traditional applications, pink bar fiberglass rebar offers compelling advantages in specific scenarios, particularly where corrosion resistance and lightweight properties are paramount.

As the construction industry evolves and sustainability becomes increasingly important, the use of innovative materials like pink bar fiberglass rebar is likely to grow. Engineers and contractors should carefully evaluate project requirements, environmental conditions, and long-term costs when choosing between these reinforcement options.

By understanding the strengths and limitations of both materials, construction professionals can make informed decisions that optimize structural performance, durability, and cost-effectiveness in their projects.

FAQs

- Is pink bar fiberglass rebar stronger than steel rebar?

Pink bar fiberglass rebar often has higher tensile strength but lower modulus of elasticity than steel rebar. - Can fiberglass rebar be bent on-site like steel rebar?

No, fiberglass rebar cannot be bent on-site and requires pre-fabricated shapes for non-straight applications. - How does the cost of fiberglass rebar compare to steel rebar?

Fiberglass rebar has a higher initial cost but can offer long-term savings due to reduced maintenance and longer service life. - Is fiberglass rebar suitable for all construction projects?

Fiberglass rebar excels in corrosive environments but may not be ideal for all applications, especially those requiring high ductility. - Does fiberglass rebar require special handling during installation?

Yes, fiberglass rebar requires careful handling to prevent damage and may need different cutting tools compared to steel rebar.