When it comes to choosing materials for roofing, skylights, or other construction projects, two popular options often come to mind: polycarbonate and fiberglass. While these materials may seem similar at first glance, they have distinct characteristics that set them apart. Understanding these differences is crucial for making an informed decision that best suits your specific needs.

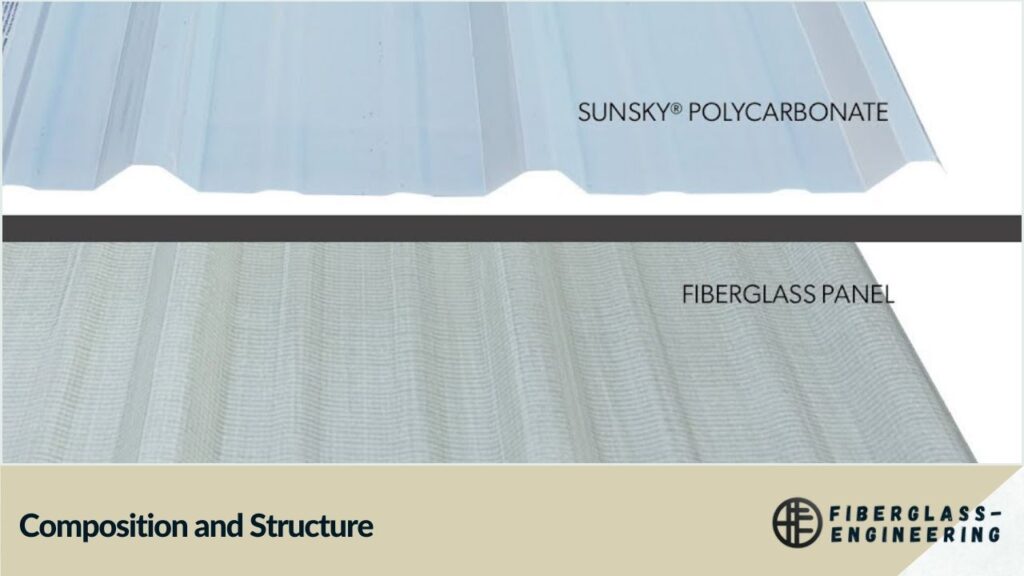

Composition and Structure

Polycarbonate is a thermoplastic polymer known for its remarkable strength and versatility. It's composed of carbonate groups and bisphenol-A, resulting in a material that's both lightweight and incredibly durable. Polycarbonate sheets are available in various thicknesses and can be molded into different shapes, making them highly adaptable for various applications.

Fiberglass, on the other hand, is a composite material made by reinforcing plastic with glass fibers. This combination results in a strong, lightweight material that's resistant to many environmental factors. Fiberglass is often used in the form of sheets or panels and can be customized with different resins to enhance specific properties.

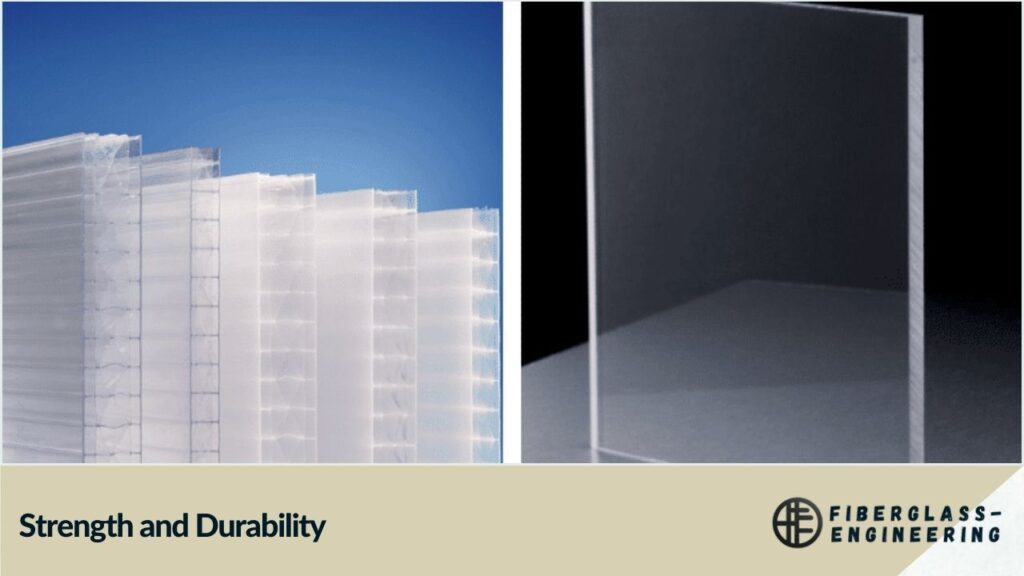

Strength and Durability

One of the most significant advantages of polycarbonate is its exceptional strength-to-weight ratio. Polycarbonate sheets are approximately 200 times stronger than glass of the same thickness, yet they weigh significantly less. This remarkable strength makes polycarbonate highly resistant to impact and breakage, making it an excellent choice for areas prone to severe weather conditions or potential impacts.

Fiberglass is also known for its strength and durability, but it approaches these qualities differently. While not as impact-resistant as polycarbonate, fiberglass excels in its ability to withstand a wide range of temperatures without losing its structural integrity. It's also highly resistant to corrosion and chemical damage, making it suitable for harsh environments.

Light Transmission and UV Resistance

Polycarbonate sheets are designed to allow light transmission, whether they're opaque, translucent, or transparent. This property makes them ideal for applications where natural light is desired, such as skylights or greenhouse roofing. Moreover, polycarbonate sheets are typically treated with a UV-resistant coating, which helps maintain their clarity and color over time, even when exposed to direct sunlight.

Fiberglass, while capable of allowing light transmission, generally diffuses light more than polycarbonate. This can be advantageous in situations where glare reduction is important. However, fiberglass is less resistant to UV radiation compared to polycarbonate. Over time, prolonged exposure to sunlight can cause fiberglass to yellow or become less transparent, potentially affecting its aesthetic appeal and light transmission properties.

Weather Resistance

When it comes to weather resistance, polycarbonate has a clear advantage. Its inherent properties make it highly resistant to extreme temperatures, both hot and cold. Polycarbonate sheets can maintain their structural integrity and appearance even in harsh weather conditions, including heavy rain, hail, and intense heat.

Fiberglass, while generally weather-resistant, has some limitations. It performs well in moderate climates but may struggle in extreme heat. Prolonged exposure to high temperatures can cause fiberglass to soften or warp, potentially compromising its structural integrity. Additionally, fiberglass may be more susceptible to damage from hail or other high-impact weather events compared to polycarbonate.

Cost and Maintenance

In terms of initial cost, fiberglass is often the more affordable option. However, it's essential to consider long-term costs as well. Polycarbonate, while potentially more expensive upfront, generally requires less maintenance over time. Its durability and resistance to damage mean that replacement and repair costs are typically lower in the long run.

Fiberglass, while initially cheaper, may incur higher maintenance costs over time. It's more prone to scratches and surface damage, which can affect its appearance and performance. Additionally, fiberglass may require more frequent cleaning and potentially specialized cleaning products to maintain its appearance and functionality.

Applications and Versatility

Both polycarbonate and fiberglass have a wide range of applications in construction and design, but their specific properties make them better suited for different uses.

Polycarbonate is often preferred for:

- Skylights and roof lights

- Greenhouse roofing

- Architectural canopies

- Sound barriers

- Safety glazing

Fiberglass is commonly used for:

- Boat hulls and marine applications

- Automotive body parts

- Insulation

- Shower enclosures

- Corrugated roofing panels

Environmental Considerations

In today's eco-conscious world, the environmental impact of construction materials is an important consideration. Polycarbonate has the advantage of being 100% recyclable, which aligns with sustainable building practices. When properly recycled, polycarbonate can be repurposed into new products without losing its essential properties.

Fiberglass, while durable and long-lasting, presents more challenges in terms of recycling. The composite nature of fiberglass makes it difficult to separate its components for recycling. However, efforts are being made in the industry to develop more effective recycling methods for fiberglass products.

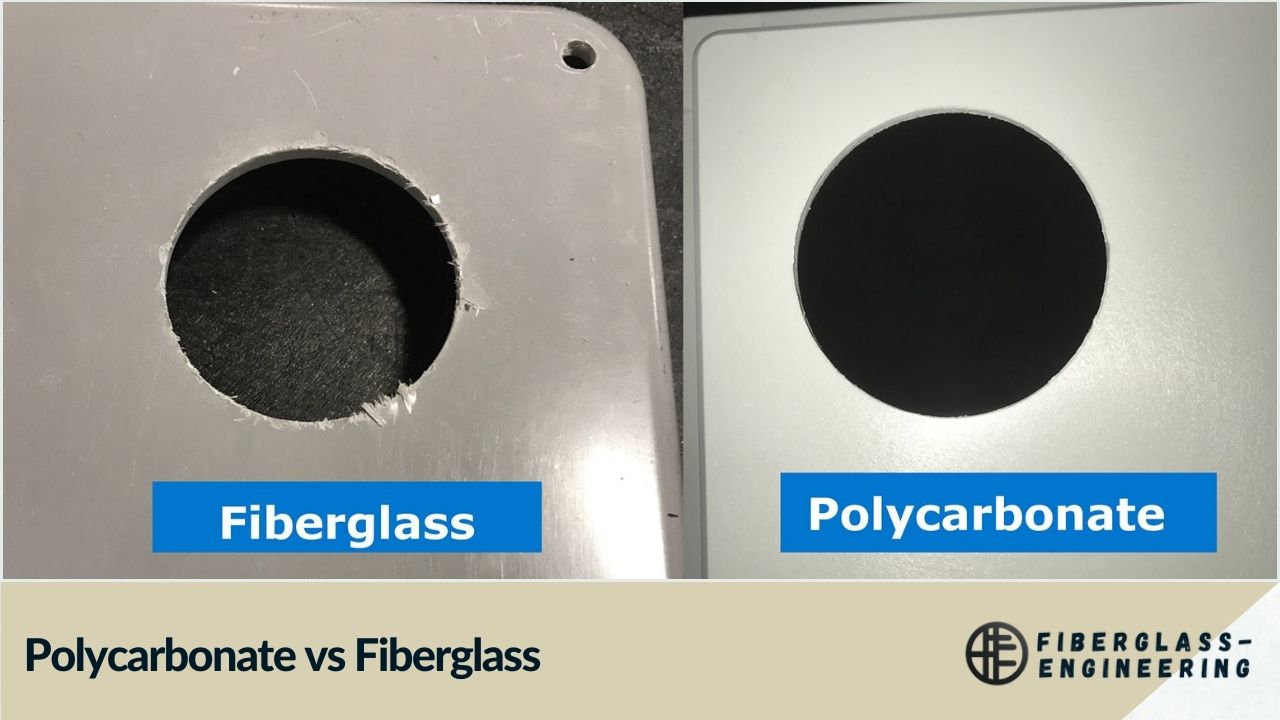

Installation and Workability

The ease of installation and workability of these materials can significantly impact project timelines and costs. Polycarbonate sheets are generally easier to work with due to their lightweight nature and flexibility. They can be easily cut, drilled, and bent on-site without special tools, making installation relatively straightforward.

Fiberglass, while still workable, requires more caution during installation. Cutting or drilling fiberglass can release glass fibers, which can be irritating to skin and lungs. Proper safety equipment and ventilation are necessary when working with fiberglass. However, fiberglass does offer the advantage of being easily moldable into complex shapes, which can be beneficial for certain applications.

Conclusion

Choosing between polycarbonate and fiberglass ultimately depends on the specific requirements of your project. Polycarbonate excels in strength, light transmission, and weather resistance, making it ideal for applications where these qualities are paramount. Fiberglass offers affordability and versatility, particularly in applications where its unique properties are advantageous.

By carefully considering factors such as durability, maintenance requirements, cost, and environmental impact, you can make an informed decision that best suits your needs. Whether you opt for the crystal-clear strength of polycarbonate or the versatile durability of fiberglass, both materials offer unique benefits that can enhance the quality and performance of your construction or design project.

FAQs

- Which is stronger, polycarbonate or fiberglass?

Polycarbonate is generally stronger and more impact-resistant than fiberglass. - Is polycarbonate more expensive than fiberglass?

Initially, polycarbonate is often more expensive, but it may be more cost-effective long-term due to lower maintenance needs. - Which material is better for outdoor use?

Polycarbonate is typically better for outdoor use due to its superior UV and weather resistance. - Can both materials be used for roofing?

Yes, both can be used for roofing, but polycarbonate is often preferred for its durability and light transmission properties. - Which material is more environmentally friendly?

Polycarbonate is 100% recyclable, making it more environmentally friendly than fiberglass, which is harder to recycle.